RETROFITTING with UV107 systems using traditional lamps

The deepening of knowledge has led to the development of second-generation UV radiation sources: LEDs (Light Emitting Diodes). When comparing UV lamps and UV LEDs, the latter have several advantages.

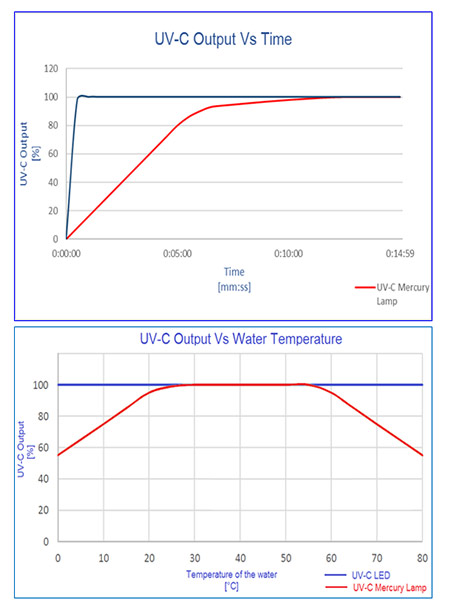

Unlike mercury vapor lamps, which take a few minutes to reach 100% disinfectant power, LEDs are able to instantly express their maximum power. This opens the doors to new possibilities for UV disinfection with discontinuous or pulsed flow.

UV-C LEDs are suitable for discontinuous operation, as they surpass the technological limit of mercury vapor lamps that allow only a limited number of daily starts (5 or 6). This capability of LEDs can be leveraged in highly discontinuous applications, such as domestic purification systems.

The extremely compact size allows for the placement of LEDs in specific points of the system, optimizing the design. For specific applications, it's possible to select LEDs with particular wavelengths. This enables obtaining the most effective wavelength for each bacterial strain.

UV lamps exchange heat directly with the water to be treated, while LEDs exchange heat directly with the environment. Additionally, UV lamps are strongly affected by the water temperature. Finally, unlike UV lamps, LEDs do not contain mercury.

Mentioned advantages of UV LEDs, compared to traditional low or medium pressure lamps, have made this technology interesting for some applications.

UV LED systems are currently developed to disinfect drinking water in point-of-use applications with the advantage of low power consumption and almost no maintenance.

UV LED disinfection systems have the potential to overcome the limitations of current UV mercury lamp systems.

SITA, with a background of experience in water treatment since 1982, has developed the first UV LED disinfection systems capable of treating from 1 to 10 liters per minute, which will replace the now renowned UV 107.

Programma Regionale FESR 2021-2027 – Azione 1.2.3 "Sostenere l’introduzione di pratiche e tecnologie digitali nelle imprese”.

Bando “Supporto allo sviluppo di progetti di digitalizzazione nelle micro, piccole e medie imprese” - Anno 2024.