SITAOP

Water is an important resource that humanity must protect. Intensive industrial use is contaminating it with chemical and organic substances. These substances are subjected to conventional treatment with insufficient results (which do not meet current regulations). But wastewater is being discharged into our sea, rivers, lakes, and soil with a high risk of contaminating our water resources to be used or reused. The same happens with industrial air pollution.

On the other hand, urban wastewater is increasingly polluted by well-known and emerging contaminants.

Water, wastewater and industrial gases need AOP (Advanced Oxidation Process) to remove organic and non-organic material.

Increasingly stringent regulations are forcing industries to use increasingly effective treatments.

What is AOP

A complex process that combines different technologies to generate hydroxyl radicals for the oxidation and degradation of contaminants. Three well-known treatments - Peroxide, Ozone, and UV Rays - are used in all possible combinations. The right configuration, whether using one, two, or all treatments, is studied on a case-by-case basis to achieve perfect synergy and the best results.

Why AOP

The SITA-AOP unit is the natural evolution of SITA's experience in UV technology and water treatment in general. SITA engineers have been engaged in the design and production of AOP treatments for many years. This experience, in combination with SITA's global partners and customers experienced in all types of fluid/gas treatment, leads to the best solution in terms of EED (Electrical Energy Demand) and chemical consumption.

THE MOST COMMON POLLUTANTS ARE:

- Volatile organic compounds (Voc)

- Polycyclic aromatic hydrocarbons (PAhs)

- Polychlorinated biphenyls (PCBs)

- Total organic carbon (TOC)

- Tetramethylammonium hydroxide (TMAH)

- Methyl pyrrolidone (NMP)

- Dimethyl sulfoxide (DMSO)

- Glycols

- Alcohols

- Urea

- Ibuprofen

- Pesticides

- Odor, color and taste

How do SITAOP experts work?

SITA experts collect the treatment target and values such as (but not limited to): TOC, BOD, COD, PH, alkalinity. Then, in cooperation with SITA distributors, who have gained experience in AOP over the past 30 years, they size and offer the best solution.

Alternatively, a pilot-scale unit can be used to process a volume of sample fluid in the SITA laboratory.

The pilot-scale system can also be provided to test and simulate a full-scale unit on site. This approach helps reduce setup costs and risks when moving to a full-scale project.

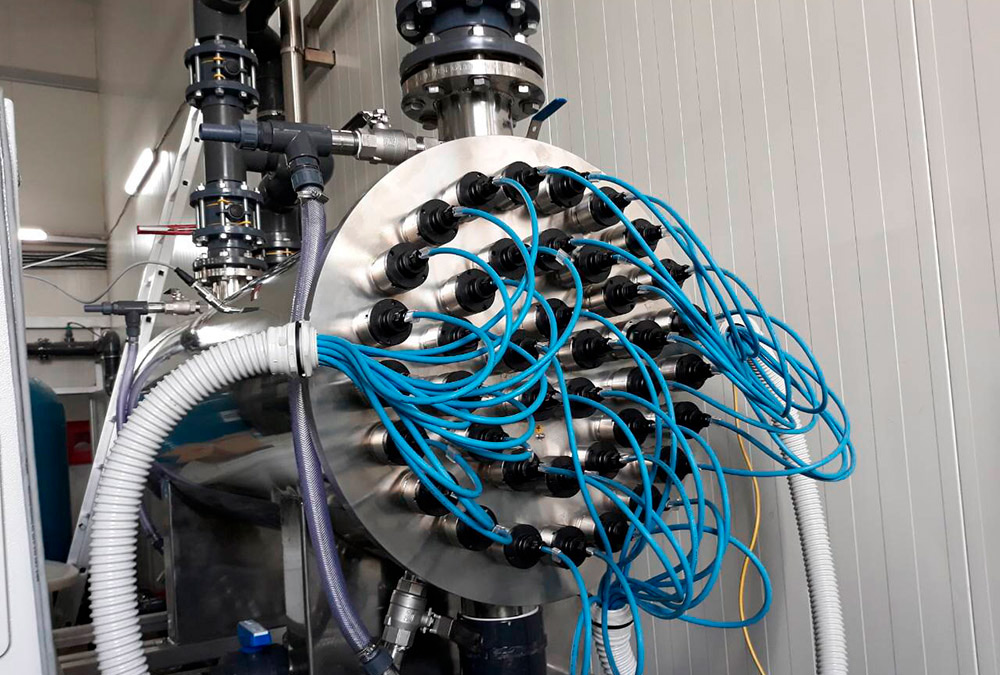

Pompe SITA Lab pumps: 2,5 l/min; 1 m3/h, 80 m3/h to 200 m3/h (as shown in the imagine)

Serbatoi SITA Tanks: from 180 litri, 1 m3, 10 m3 to 30 m3 (as shown in the imagine)

The pilot-scale system can also be provided for testing and simulating a full-scale unit on-site. This approach helps reduce setup costs and risks when transitioning to a full-scale project.

What does SITA supply?

For both pilot scale and full-scale units, SITA manufactures skids, UVs, and SS piping. Other parts are selected from the best suppliers (and SITA's long-time customers).

SITAOP treatment features:

- Integrated system controlled by a main PLC.

- Augmented reality (for startup, settings, maintenance, and troubleshooting). Complete dosage control of O3, H2O2 and UV.

- Pump and valve control (if automatic).

- Customized configuration.

- Preassembled skid or separate easy-to-assemble units.

- Plug and play.

- Design and Made in Italy.

FROM PILOT PLANT TO THE COMPLETE TREATMENT